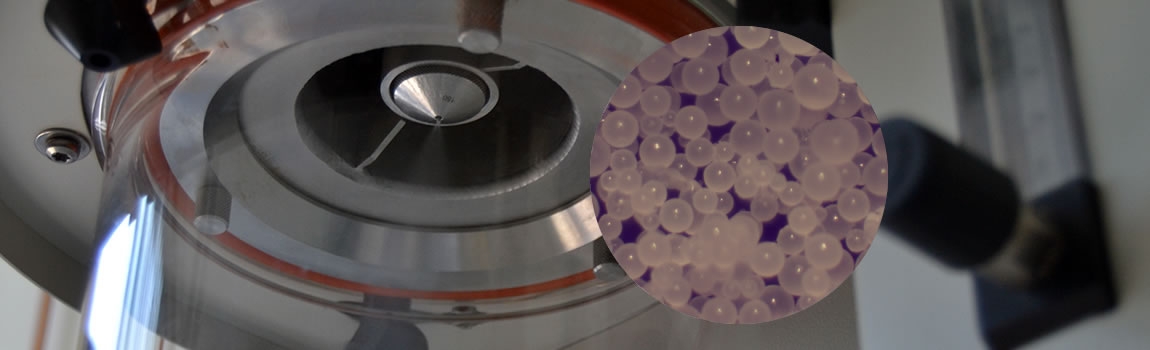

The spray chilling (or spray congealing) technique involves the atomization of a mixture of molten substances in an environment with a temperature lower than the solidifying temperature of that same material. The sudden temperature drop determines the solidification of the atomized material and the formation of nearly spherical solid micro or nano-particles. There are multiple applications of the spray chilling technology: as an example, the encapsulation of milk enzymes, vitamins or aromas within the food sector. In the pharmaceutical field, the use of lipidic matrix systems, which can also be produced using this technique, allow to determine predictable and stable release performances of active ingredients, is becoming increasingly frequent.

APTSol is equipped with a spray chilling system dedicated to the development of your lipidic formulations. If you are interested in the spray congealing technology, please do not hesitate to contact us.

Our spray congealing technology

We have equipped our spray dryer with new features that allow it to turn into an effective spray congealing system for the development of your products.

Product volume: 20 - 300 mL

Product temperature: 30 - 150 °C

Nozzle diameter: 0,7 - 2,0 mm